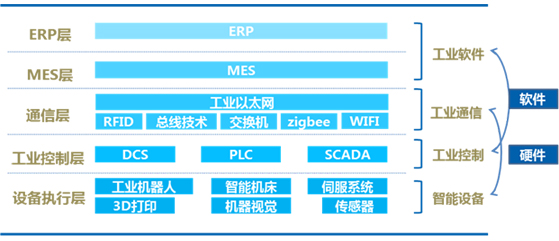

Manufacturing Execution Systems (MES) are computerized systems used in the work shop execution of manufacturing. MES works in real time to enable the control of multiple elements of the production process (e.g. inputs, personnel, machines and support services). The plant floor can be optimized to improve production output.

MES may operate across multiple function areas, for example: manufacturing data, resource scheduling, order execution and dispatch, inventory, quality, human resources, equipment, purchasing, cost and project management; process control, data integration analysis, to create a solid, reliable, comprehensive and feasible collaborative manufacturing management platform.

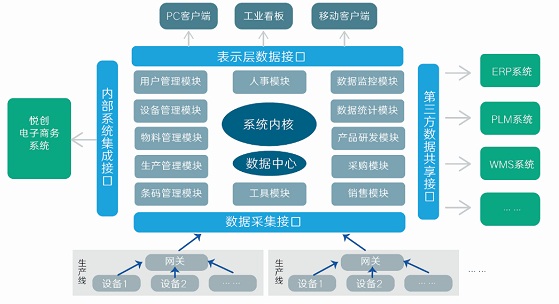

FRD MES integrated construction uses distribution and big data technology, hadoop and redis memory database for designing, cloud processing and fast data access, and real-time data operation. Nginx is equipped to improve the amount of web access concurrency. Support 10 million devices online at the same time. Use Kafka to read the news quickly to prevent loss of data, and the news are transferred to multiple spark services for distributed processing.

The system adopts CS+BS architecture for design, uses java for programming, and has good portability and cross platform. It uses HTML5 and Cordova programming on the mobile phone and quickly updates app functions without updating the terminal.

In combination with the gateway equipment, relay equipment and wireless acquisition module developed by FRD, use wireless protocols (e.g. 433MH, WIFI, ZIGBEE, 4G, etc.) for data acquisition. It can facilitate data interaction with third party software / hardware.