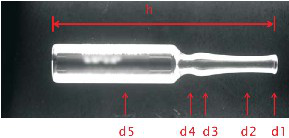

Application: On - Line Pill Glass Bottle Size Monitoring System

Background: Medicine is a matter of people’s livelihood. Its production is a very strict process. Injection bottles should go through all aspects of strict testing. In the dust-free and germ-free workshop, how to guarantee maximum avoidance of personnel contact and realize rapid detection and measurement, is a difficulty for many engineers.

This case provides a rapid non-contact online measurement method.

(Product)

Requirements:

→Rapid detection of multiple sizes of transparent pill glass bottles;

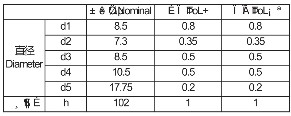

→When the product reaches the specified position, trigger the camera to take pictures, and at the same time, trigger lights of both sides. After pictures are taken, send a signal, switch off the upper light and switch on the lower light.

→Processed by camera software, the results can be displayed through sound and light alarm.

→The product is automatically rotated to achieve multiple sampling and analyses of bottle measurement results.

(Accuracy requirements)

(On-site equipment picture) (Internal diagram)

System Features:

→Detection accuracy of 0.02mm

→Smart camera program; simple and fast

→Collect several groups of data each time; complete test report

→Automatically calculate CPK, and the results are stored in the database

→Achieve full automation and visualization